Every job in metal fabrication comes down to precision. A fraction of a millimeter off, and suddenly nothing fits the way it should. According to industry reports, over 30% of manufacturing delays are directly tied to fabrication errors. And while big issues get the spotlight, it’s usually the repeatable, everyday mistakes that cost the most over time.

Whether you’re managing a large team or running a smaller shop, keeping an eye on these common missteps can help you stay on track. You’ve already invested in your people and your machines; now it’s time to protect that investment with sharper decisions.

In this article, you’ll find seven easy-to-overlook mistakes that affect metal fabrication and practical advice to avoid them.

1. Poor Planning at the Start

It sounds basic, but skipping over the planning phase is one of the biggest reasons jobs go sideways. Rushed timelines, unclear drawings, or missing material specs often lead to scrap, rework, or delivery delays.

You need a clear scope from the beginning. Double-check the drawings. Review tolerances. Walk through the job flow before any cutting begins. It’s easier to adjust early than to fix errors after metal’s been shaped.

2. Inconsistent Cuts or Edges

This is a problem that shows up more often than you’d think. When your cuts aren’t clean or accurate, you’re likely to struggle during welding or assembly. Whether it’s uneven gaps or pieces that don’t quite fit, the result is more time spent fixing mistakes that could’ve been avoided.

A lot of this comes down to the cutting method. Some shops still rely on outdated or less efficient tools, which might work for certain tasks but don’t always hold up under pressure, particularly for more demanding tasks.

When it comes to cutting aluminum, using the right technique and equipment matters; plasma cutting, for instance, offers both speed and precision for a wide range of thicknesses. It’s become a go-to method not just because it’s fast, but because it consistently delivers cleaner cuts with less waste.

3. Using the Wrong Material

The incorrect choice of grade or thickness of metal is an expensive error. It could be inadequate for the structural requirements of the job, or it could respond in a different manner while bending or cutting.

This normally happens when the teams quickly substitute due to inventory shortages or due to price pressure. Always double-check the specifications prior to making material decisions. A less expensive choice today may lead to significant problems in the future, particularly if the ultimate application is pressure, weight, or exposure.

4. Skipping Equipment Maintenance

You might be surprised how many shops push their tools until something breaks. Welding gear, cutting tables, and bending machines all need upkeep. If you’re not doing regular checks, small issues can snowball into major downtime.

It’s not just about avoiding breakdowns. Well-maintained machines also deliver more consistent results. Replace worn consumables on schedule. Calibrate machines as needed. A few minutes spent each week can add up to fewer headaches later.

5. Underestimating Fit-Up and Welding Prep

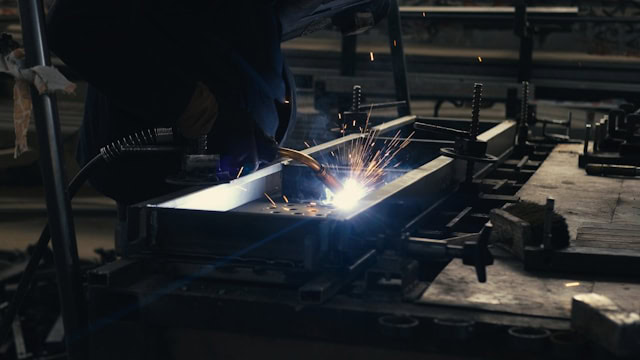

Sometimes the pieces are cut right, but the welds just don’t come together. Gaps, misalignments, or uneven joints often show up because no one took the time to prep the surfaces properly.

You can avoid this by ensuring edges are clean, bevels are correct, and parts are clamped securely before striking an arc. A little more prep time means stronger welds and fewer quality control issues. Rushing this part only adds extra grinding or rework hours later.

6. Weak Quality Checks

Some businesses check one item in a batch, while others postpone checks until the very last step. Both methods are dangerous in their own ways.

Incorporating mini quality checks on every step minimizes the damage. It doesn’t have to be a full stop: verifying part dimensions when they are cut, judging weld penetration, and a jig check during assembly. Early identification, without grinding the machine to a halt, keeps the processes sleek. It minimizes rechecks down the line.

7. Ignoring the Importance of Training

A common misconception is that once someone knows how to weld or run a cutter, they don’t need much more. But fabrication is always evolving. Materials change. Equipment updates. Even job expectations shift.

Shops that invest in training usually see fewer mistakes, better output, and higher morale. You don’t always need full courses sometimes; peer mentoring or short skill refreshers do the trick when your team understands both the tools and the “why” behind processes, they naturally make better decisions on the floor.

Final Thoughts

Mistakes in metal fabrication are often avoidable. Most come down to habits, communication, and taking the time to set things up right. You don’t need to overhaul your entire operation to see improvement, just pay closer attention to the basics that are easy to overlook during a busy day.

Whether you are working with structural steel or lighter materials like aluminum, each step plays into the next. A cleaner cut makes a better weld. A better weld makes for a smoother assembly. It all connects.

So take a step back once in a while. Review your process. Ask your team what’s working and what’s not. Small adjustments can make a big difference in efficiency, consistency, and results. And in a competitive space like fabrication, that edge is always worth it.